Chapter 18 - Liquid sludge treatment (98 pages)

- Introduction

- 1.General sludge treatment lines

- 2.Thickening

- 2.1.Static thickener

- 2.1.1.Description (figure 5 and photo 2)

- 2.1.2.Design

- 2.1.3.Setting up

- 2.1.4.High loaded static thickener

- 2.1.5.Filter or biofilter wash water thickening

- 2.2.Dynamic thickening

- 2.2.1.Flotation

- 2.2.2.Drainage

- 2.2.3.Centrifugation

- 3.Sludge conditioning

- 3.1.Chemical conditioning

- 3.1.1.Mineral reagents

- 3.1.2.Synthetic polyelectrolytes

- 3.2.Heat treatment

- 3.2.1.Advantages of heat treatment

- 3.2.2.Restrictions on use

- 3.2.3.Setting up sludge heating

- 3.3.Other various conditionings

- 3.3.1.Freezing-Thawing

- 3.3.2.«Conditioning» using inert additives

- 3.3.3.Treatment using electro-osmosis

- 3.3.4.Toxic sludge stabilising agents

- 4.Liquid sludge stabilisation

- 4.1.Anaerobic digestion

- 4.1.1.Parameters affecting anaerobic digestion efficiency

- 4.1.2.Results and advantages of digestion

- 4.1.3.Biogas re-use

- 4.1.4.Sludge digester types and dimensioning

- 4.1.5.General dimensioning data

- 4.1.6.Degrémont sludge digester design

- 4.1.7.Commissioning and operating a digestion process

- 4.1.8.Processes open to improve anaerobic digestion performance

- 4.2.Aerobic stabilisation

- 4.2.1.Aerated storage

- 4.2.2.Mesophilic aerobic stabilisation

- 4.2.3.Thermophilic aerobic digestion (or TAD)

- 4.3.Chemical stabilisation - Lime treatment

- 4.3.1.Liquid sludge lime treatment

- 4.3.2.Lime treatment of dewatered sludge

- 5.Belt filters

- 5.1.Introduction

- 5.2.Belt filter filtration: principle

- 5.3.Degrémont range

- 5.3.1.Superpress LP and HP filters

- 5.3.2.The GDPress: a belt filter for the smaller plants

- 6.Centrifugation

- 6.1.Sludge centrifugation suitability

- 6.2.Continuous cylindro-conical decanter

- 6.3.Main geometric parameters (figure 26)

- 6.3.1.Bowl diameter D and LT/D ratio

- 6.3.2.Angle of conicity

- 6.3.3.Thread height H between screw and bowl

- 6.3.4.Space separating the screw and the bowl in the conical section

- 6.3.5.Clarification surface area S with a maximal pool depth

- 6.3.6.Bowl internal capacity

- 6.3.7.Counter courant or co-current system

- 6.3.8.S factor

- 6.3.9.Screw extractor

- 6.4.High pressure centrifuges (figure 29)

- 6.4.1.Parameters used to improve dry solids content

- 6.4.2.Operating parameters

- 6.4.3.Performances

- 6.4.4.Direct centrifugation

- 6.5.Setting up

- 6.6.Centrifugation: its advantages and its limitations

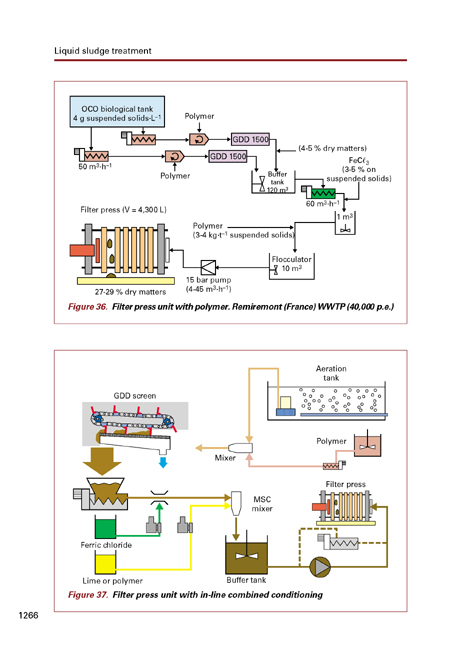

- 7.Filter press

- 7.1.Numerical characterisation of filterability

- 7.1.1.Specific resistance to r filtration

- 7.1.2.Compressibility factor

- 7.1.3.Dryness limit

- 7.2.Conventional recessed plate filter press

- 7.2.1.General description of a conventional recessed plate filter press (figure 34)

- 7.2.2.Technologies applied

- 7.2.3.Filtration cycle

- 7.2.4.Filter press dimensioning

- 7.2.5.Performances achieved with mineral conditioning

- 7.2.6.Performances achieved with polymer conditioning

- 7.3.Membrane plate filter press

- 7.3.1.Description-performances

- 7.3.2.Heated filter press

- 7.4.Automatic filter press

- 7.5.Other filtration processes

- 7.5.1.Dryer beds on sand layer

- 7.5.2.Dewatering lagoons

- 7.5.3.Rotating drum vacuum filters

- 7.5.4.Screw presses (figure 41)

- 8.Sludge handling and storage

- 8.1.Sludge handling

- 8.2.Sludge storage (table 27)

- 8.3.Safety

Introduction

A sludge treatment system can only be properly designed if we know the answers to the following three questions:

- what is the quality of sludge to be treated?

- how much suspended solids has to be processed?

- what is the intended potential end usage of this sludge?

Sludge quality depends on the pollutants contained in the wastewater entering the plant but mainly on the treatments carried out (see chap. 2 § 6.1.) and will have a major effect on the forecast performance of the various processes: impact on dry solids content, on the type of reagents and amounts used, on the choice of equipment. For instance, if the sludge is hydrophilic (presence of biological sludge, of hydroxide sludge, of organic matter, etc.), this will have an adverse effect on dewatering performance (relatively low final dry solids content). On the other hand, if the sludge is hydrophobic (presence of crystalline sludge, of heavy mineral sludge, of primary settled sludge...), dry solids content performance will tend to be quite good.

The quantities (suspended solids) set equipment investment levels and impose certain financial options. Additionally, any rational wastewater treatment plant design must address a major concern: it must attempt to significantly reduce the mass of waste products created by the treatment process. This reduction can be addressed within the water system itself by using organic and non-mineral reagents or very low loaded biological treatment, or even using processes such as Biolysis. Clearly, this reduction can also be dealt with in the sludge system (anaerobic digestion, OM incineration, using an organic conditioner...).

The final disposal of sludge (see chap. 2 § 6.3.) will have a significant influence on the equipment selected:

- whether or not the sludge has to be stabilised;

- whether or not the sludge has to be sanitised;

- whether or not a particular reagent should not be used;

- whether or not a minimum dry solids content has to be achieved;

- whether or not a solid final product has to be produced;

- whether or not an alternative system is required;

and even, when selecting the water line, for instance, by aiming for sludge that has a high organic matter content and a high dry solids content so that it can be incinerated...

Therefore, any study concerning sludge end usage must include:

- a comparative financial analysis (investment costs and operating costs);

- an examination of the sustainability of the system under consideration, while allowing for the relevant regulations (see chap. 2 § 6.3.3.).